|

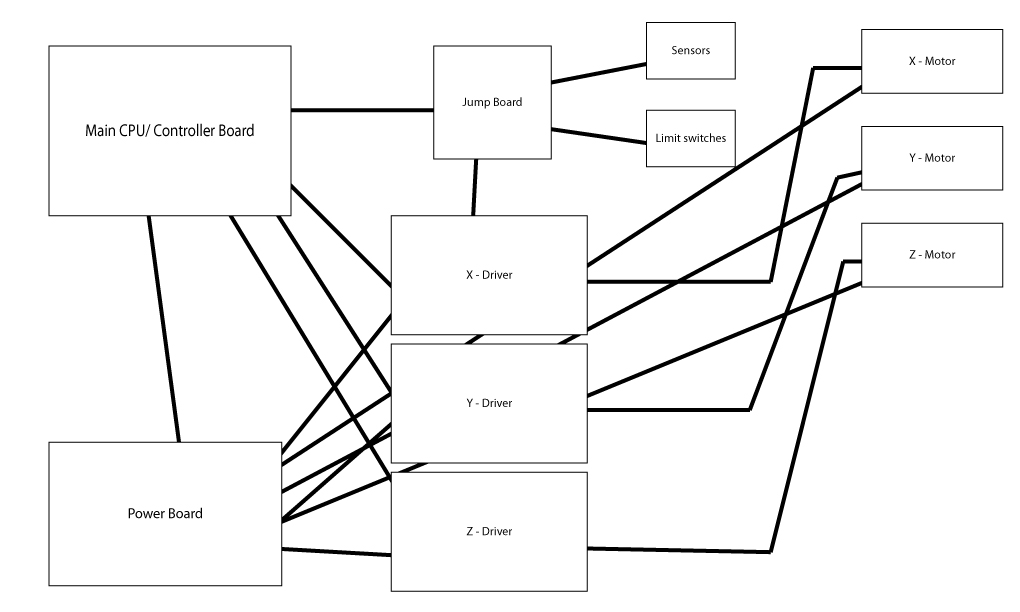

I get quite a few questions about electronics and boards in embroidery machines. This is some basic information about the boards involved. Your commercial embroidery machine is basically a CNC Sewing machine. CNC stands for 'computer numerical control' which is a system that tells a machine to move to this coordinate and do something. then move tho this location and do something else. You may use a CNC machine every day and not know it as a cnc machine. Your Printer is a CNC machine. Laser cutters, plasma cutters, 3d printers, and cnc routers are examples of other CNC machines. Again basically the machine moves to a X - Y Coordinate and then does something. Your embroidery machine moves a shirt or cap to a specific location and does a stitch. Click "Read More" to find out more information on this topic.

|

|

|

|

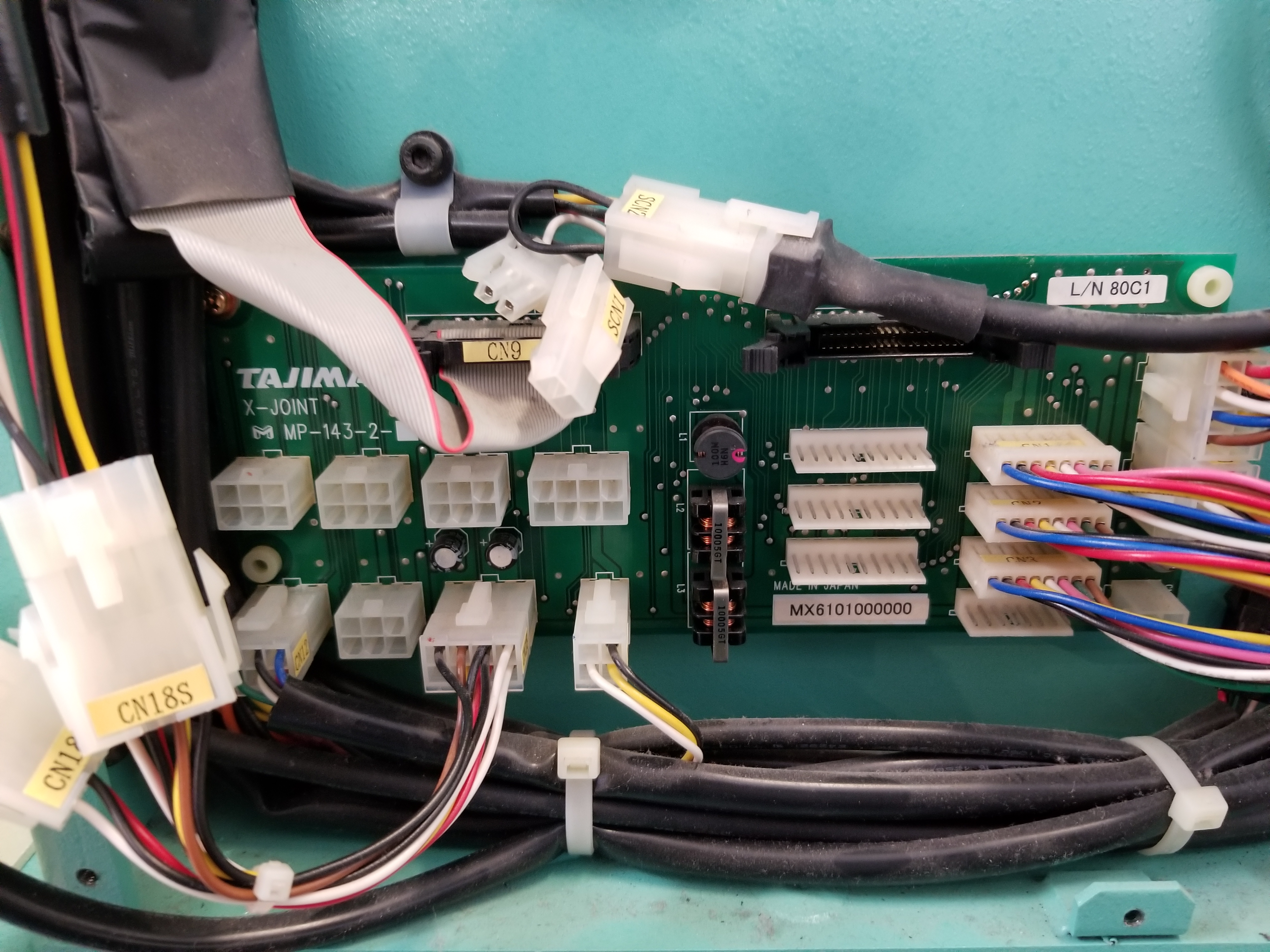

No two embroidery machines are created equally. The board layout on one machine may be totally different on the next machine. So, there is not generic set up as far as Printed Circuit Boards are concerned. Down at the basics you will have the following boards:

The boards are usually kept separate so it is more cost effective to replace or repair them. Many embroidery machines combine several boards into one board, for example the x/y drivers may be combined on one board. |

Tajima Main CPU Board

|

|

Diagnosing electical issues is sometime problematic. One board could be faulty and causing another board to seem defective.

Many times two different name brand machines can give the same symptoms but the cause of the issue could be totally differnt components.

|

SWF XY Driver Board Card

|

|

|

What are the boards and electronics in a commercial embroider machine, and how do they interact with each other?

What are the boards and electronics in a commercial embroider machine, and how do they interact with each other?